Nanomaterials by Information-Guided Design

Dominated by surfaces and interfaces, nanomaterials often display surprising physical, electronic, or mechanical properties.

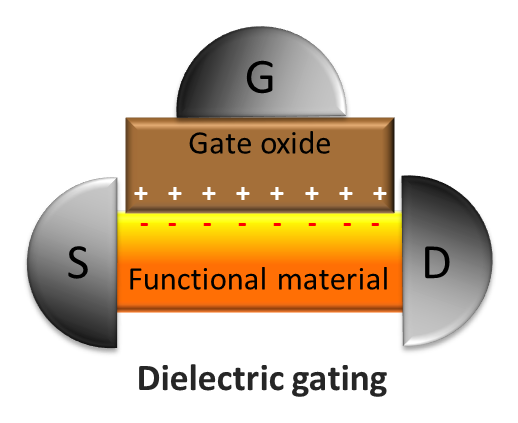

At the INT we not only produce nanomaterials and explore their properties, but also develop techniques for influencing their properties. This is done through external stimulus after the materials are produced and deposited, tremendously extending their functionality. We also work on the development and understanding of catalysts based on metallic nanoparticles.

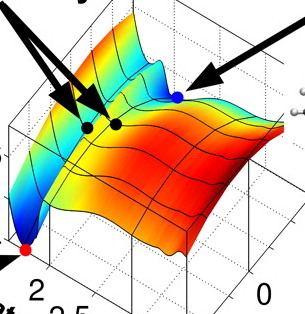

Development of AI and machine learning methods, including generative models and foundation models, with a focus on the application to materials science questions.

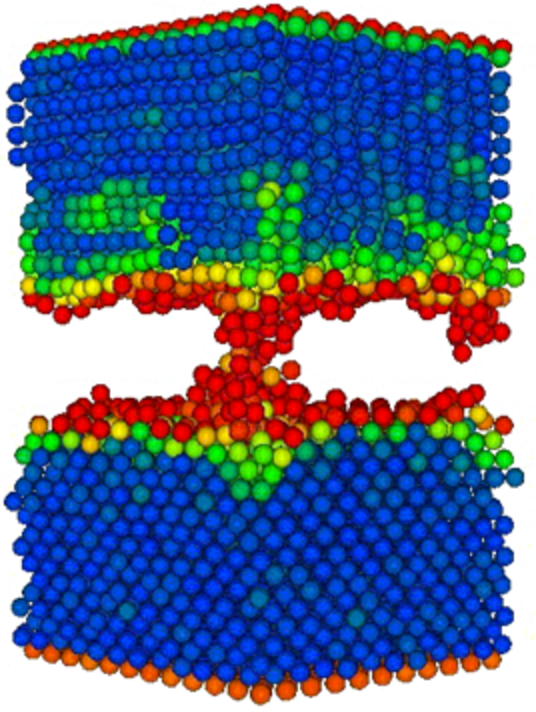

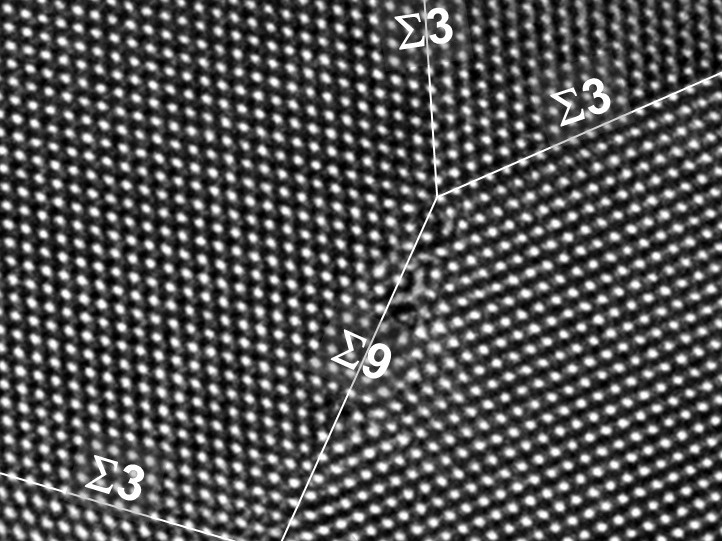

Understanding the mechanical properties of nano-crystalline materials and nano-glasses using atomistic simulations.

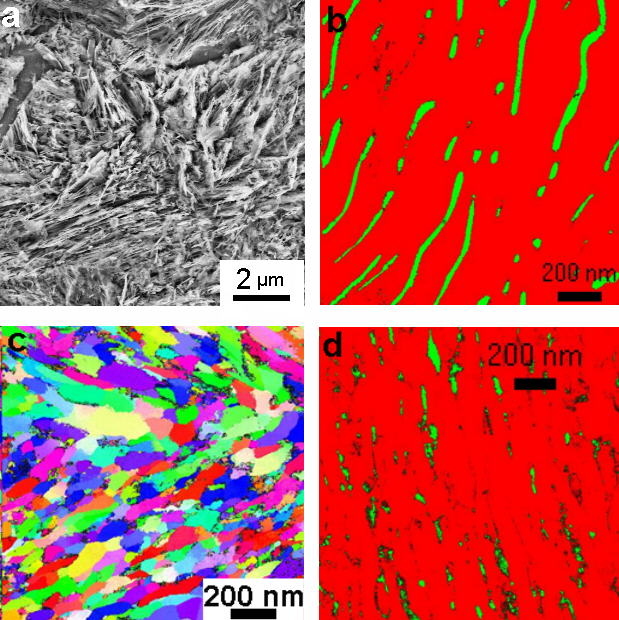

Exploring the link between atomic scale structure in model systems to micron-sized 3D structure of support materials

A novel class of non-crystalline materials with controllable atomic/electronic structures corresponding to the structures of modern technologically utilized crystalline materials

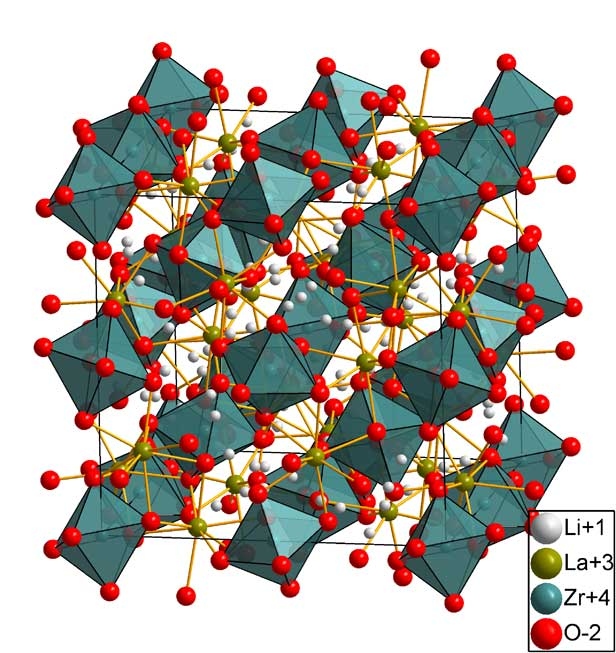

Magnetoelectric effects using charged interfaces in nanocomposites

Explaining unusual deformation behavior and developing enhanced mechanical properties

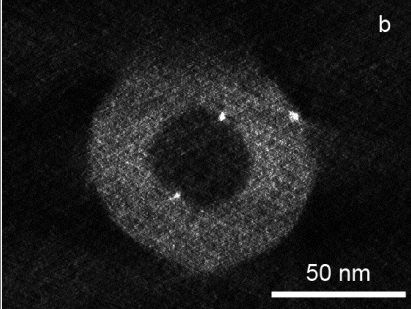

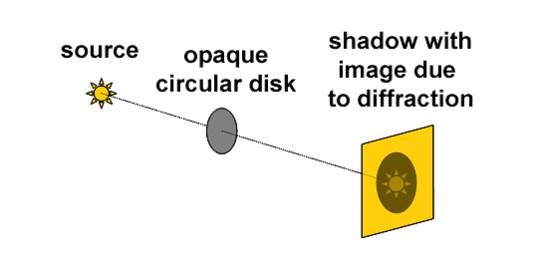

Production and characterization of cluster-based materials and particle-wave duality of clusters of increasing size

High-end electron microscopy techniques to correlate nanoscale and atomic structure with nanomaterial properties

_rdax_98.png)

Correlating size-dependent structural evolution with physical and chemical properties

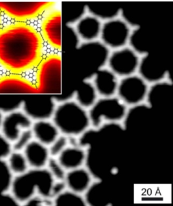

Preparing atomically precise 2D nanocarbon materials on bulk scale through self-organization and processes for growth, fractionation and nanostructuring

Simulation approaches for de-novo characterization and optimization and developing device properties with nanoscale constituents.

Modeling structures and functions of graphene, graphite and CNT for applications in electronics and data storage

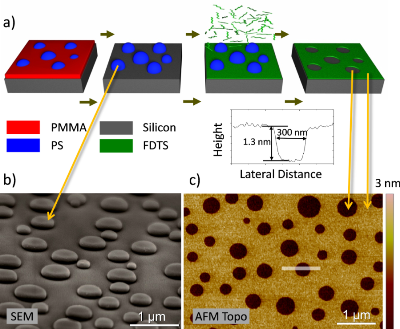

Polymer-blend lithography to produce patterned self-assembled monolayers on solid substrates featuring various functionalities

Correlations between synthesis, interface and bulk properties and macroscopic functional and structural properties