Hard Carbons as Electrodes for Sodium Batteries

Sodium-ion batteries (SIB) have emerged as a promising alternative to lithium-ion batteries due to the abundance and low cost of sodium (Na). One of the critical challenges in advancing SIB technology is the development of high-performance cathode materials. In this project, we explore the use of porous hard carbon particles as potential cathode materials for SIB, with a focus on understanding their structural and chemical properties and how they change during battery operation.

Hard carbon (HC) materials have shown promise in SIB due to their high capacity and favorable cycling stability. However, the mechanisms by which these materials operate and degrade are not fully understood. By leveraging advanced transmission electron microscopy (TEM) characterization techniques like electron tomography and electron energy loss spectroscopy (EELS), this project aims to fill the knowledge gap and provide valuable insights that could guide the design of more durable and efficient cathode materials for future SIB.

Structural Characterization Using Electron Tomography.

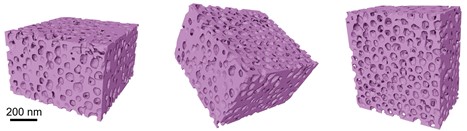

In this work, electron tomography, particularly in scanning TEM (STEM) mode, is employed to reconstruct the three-dimensional porous structure of HC. Figure 1 shows exemplary the pore structure of a HC synthesized by the group of Bernd Smarsly at the University Gießen. This advanced imaging technique allows us to visualize the internal morphology of the pores down at the nanoscale, providing crucial insights into how their structure is correlated with the intercalation of Na+ - ions. While micropores (2-5 nm) are regions where ions are trapped, mesopores with sizes of the order of 5-50nm provide pathways for ions to move into deeper regions and enhance the overall ion storage. Therefore, a well-optimized combination of micro-and mesopores can ensure rapid ion diffusion and enhance the charge/discharge rates.

One of the primary objectives is to investigate any structural alterations of the pore after it has undergone several charge-discharge cycles in a SIB. By comparing the 3D reconstructions of the material before and after cycling, we aim to identify any degradation or morphological changes that could impact the material's effectiveness as a cathode.

Figure 1. 3D rendering of the reconstructed volume of a macro porous hard carbon particle. The volume has a size of 750x700x450 nm3. The pore size in the particle is in the range of ~50 nm.

Coupling Electron Tomography with Electron Energy Loss Spectroscopy (EELS).

To gain a deeper understanding of the chemical changes occurring in the HC, we combine electron tomography with EELS. STEM - EELS is a powerful technique that allows us to study the electronic structure of materials. In HC, the carbon atoms are predominantly in an sp2 hybridized state, i.e. conductive graphitic domains. On the other hand, the sp3 hybridization would lead to a more amorphous structure and a reduction in electrical conductivity but an enhanced ion storage capacity. An optimal mixture of sp² and sp³ hybridization is critical for HC to operate effectively as an electrode material. By correlating these chemical changes with structural data from tomography, we can develop a comprehensive understanding of how cycling affects the material on both a structural and electronic level.

|

This work is founded by the German Research Foundation (DFG) under Project ID 390874152 (POLiS Cluster of Excellence). |