Prof. Dr. Peter Gumbsch

- Research Unit Chair

- Research Unit: Mechanics of Nanoscale Materials

- Room: Geb. 10.91 Rm 121

- Phone: +49 721 608-44363

- peter gumbsch ∂does-not-exist.kit edu

Karlsruher Institute for Technology

Institute for Applied Materials - Computational Materials Science (IAM-CMS)Bldg. 10.91 Rm. 121

Engelbert-Arnold-Straße 4

76131 Karlsruhe

Research Projects

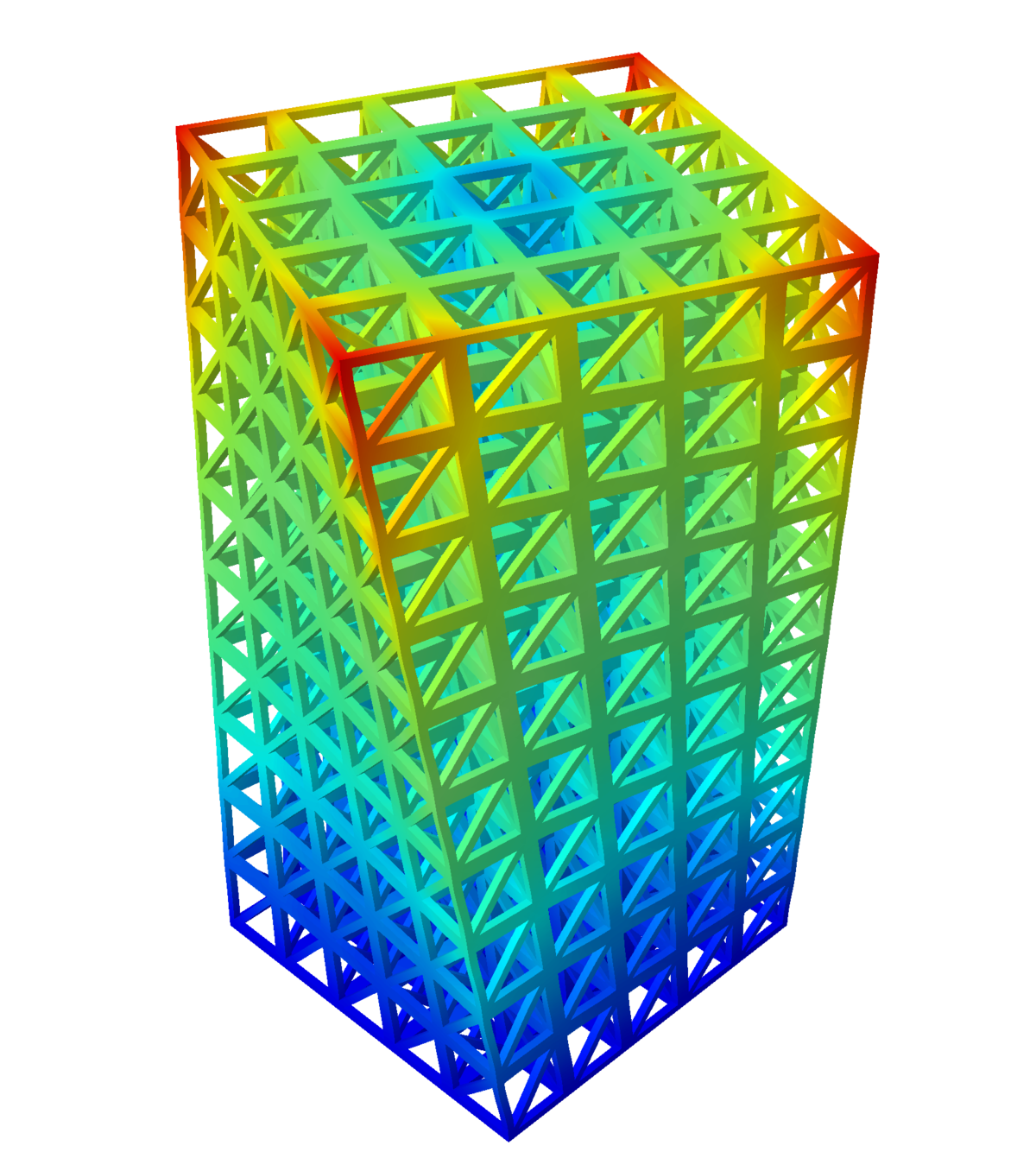

1. Mechanical Metamaterials

Metamaterials are artificial materials of tailored micro-structured functional building blocks (or "meta-atoms") with built-in mechanisms, often arranged into a 3D crystalline order. Metamaterials enable effective material properties that go quantitatively and qualitatively beyond ("meta") those of ordinary materials known from nature.

Our theoretical and mechanical studies focus on the characterization and optimization of mechanical metamaterials and address for example:

-

Programmable metamaterials:

Their macroscopic materials properties can be changed after building the material. Our designs have made use of buckling beams or gears to achieve such programmability. -

Chiral metamaterials:

They show a twist as a response to extension or compression – a deformation mode which is forbidden in classical "Cauchy" continuum mechanics. Here we have made designs that maximize chiral response, maximize the chiral moment or maximize energy storage.

2. In situ nanoCT

-

Structural characterization of various materials:

The nanoCT enables the non-destructive structural characterization of three-dimensional samples with resolution down to 50 nm. The sample is positioned in the focal spot of the X-ray beam and 2D X-ray radiographs of are acquired over up to 180°, using absorption or phase contrast modes and fields of view of 65 μm or 16 μm. The 2D projections are then reconstructed, resulting in a 3D visualization of the sample. Through further processing, the data can be segmented and quantified. -

In situ mechanical testing:

The in situ mechanical testing device allows the investigation of the inner structure of materials in time-lapsed compression, indentation and tension, to a maximum load of 0.8 N. -

In situ thermal testing (coming soon):

The in situ heating device allows the investigation of materials changes upon heating from RT up to 500 °C.

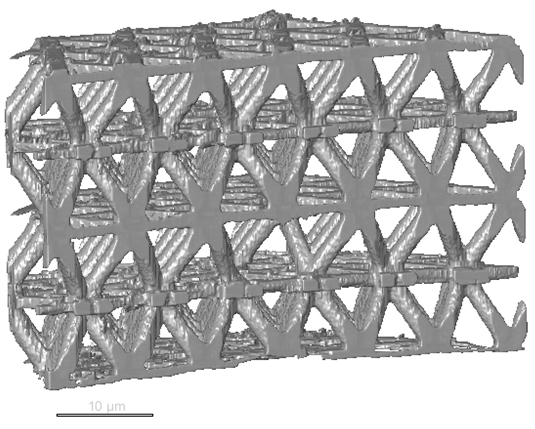

3. Cluster of Excellence 3DMM2O

As a part of the Cluster of Excellence 3D Matter Made To Order (3DMM2O), our group focuses on the design and the structural and mechanical characterization of three-dimensional (3D) metamaterials and complex microstructured materials, combining analytical mechanical approaches, numerical simulations and advanced experimental methods such as high resolution X-ray computed tomography (nanoCT) with in situ mechanical testing.

-

Tetrahedral microlattices:

We aim at an understanding of the role of defects in metamaterials for the deformation behavior of the microlattices. Using lab-based nanoCT with in situ mechanical testing, microlattices with and without introduced defects are imaged in 3D at different steps of compression. We combine the imaging experiment with theoretical analyses to observe microstructural changes as a function of mechanical loading. -

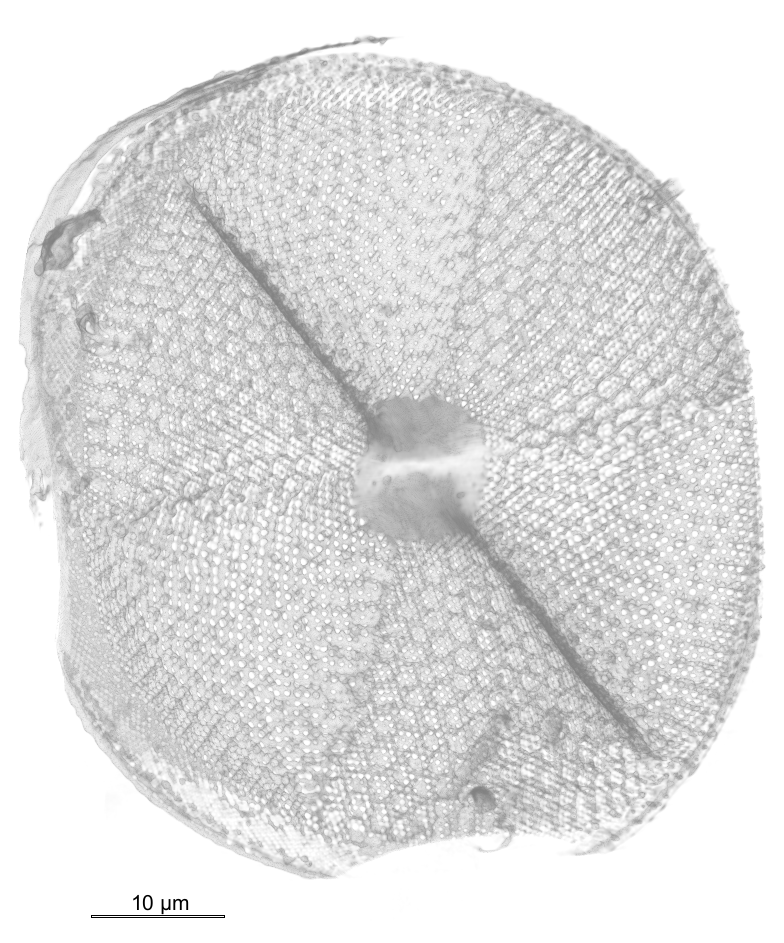

Diatoms as a biomimetic material:

Diatoms have an interesting structure and morphology, consisting of uniform and symmetrically arranged pores, which can inspire the development of new materials. Lab-based nanoCT enables the structural characterization with the quantification of pore sizes, proportion and distribution within the diatom. Stepwise in situ loading allows the observation of fracture evolution at different loading steps. -

Structural characterization of porous materials:

3D structural characterization of porous materials developed by Cluster and external collaborators, including polymers, nanocomposites, printed nanoporous structures, electrode samples, among others.